Equipment Overview

Machines are present in almost every premise these days.

Some examples of machinery include; Fabrication Equipment (such as saws, drill

presses, sheet metal presses), Bottling Equipment, Spraying Systems, Welding

Systems, Crushing Units, Mixing Systems, and so forth. All these systems

typically have a control system installed. Some of these control systems are

managed by basic electrical circuits while others are controlled by

Programmable Logic Controllers (PLCs).

Regardless of the type of control system

used, they all employ the following principles. That is, the different levels

of control with how it manipulates the materials (also known as products) in

which it was designed for.

How It Works

This framework can be used across various types of systems. It’s

designed in a way that it can be scaled, it is flexible for future expansion

and upgrading, assists with system integration, and should assist with

breakdown recovery times. What this guide does not do, is teach how to program

a PLC. It is assumed that a suitable level of programming knowledge is held by

the programmer.

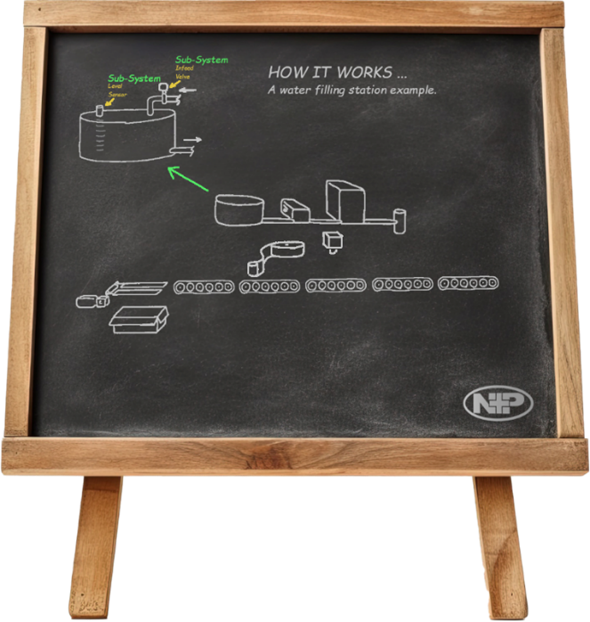

What are Sub Systems?

The best starting point in understanding how machinery works,

is looking at the basic components. A machine is made up of various sensors,

buttons, actuators and valves. Each of these components (for example a sensor),

in the confines of this document, are classified as a Sub System. These units

can be as basic as a dry contact switch or as complicated as a VSD having its

own internal CPU.

These components can be connected to a more advanced

communication medium such as Ethernet, however employing such technologies will

increase system costs as well as reduce ‘fix’ options during breakdowns. There

are also risks associated with differences in communication protocol versions

which can result in cost increases during breakdowns when equipment has become

obsolete. When keeping communication to basic forms like digital IOs and

analogue IOs, this risk can be significantly reduced.

Within this document we will use the example of a bottling assembly.

An example of a Sub System within this scenario, is that of a product liquid

level sensor (input) which is monitoring the tanks product liquid level which

is ultimately going to be used for filling bottles on the production line.

Another example is that of the valve (output) which controls the flow of the fluid

being supplied to that said tank. Both components are independent from one

another and there only link is through the control System that either listens

to their signals or tells them when to operate.

An

important point to take from this is that the communications between the

component should be reduced to a small number of Input / Outputs (IOs).

Ideally, the number of connections needs to be kept to a minimum between these

units. The reason being that it reduces the workload required for finding non

‘like for like’ parts during breakdown and provide greater options for what can

be later used if there is a desire to change the unit from the Original

Equipment Manufacturer (OEM).

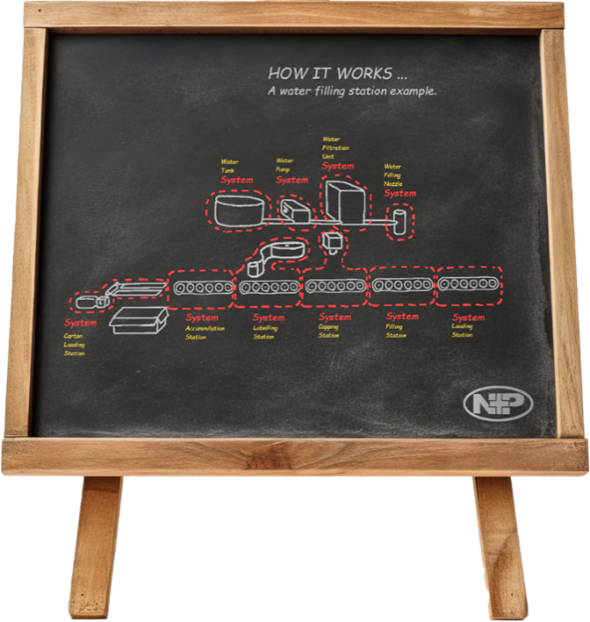

What are Systems?

The next level up from Sub Systems are Systems. System is

the term used to describe a relationship between various components (also known

as Sub System). This is typically a single point of transformation of a product

being used in the manufacturing process. It usually only involves a single

step. It usually involves monitoring and controlling various Sub Systems.

An example of a System, relating to the bottling Assembly

scenario, is that of the product liquid storage tank. The tank level needs to

be constantly monitored and filled when nearing the empty point. The purpose of

the tank is to act as a buffer between the slow product liquid supply and a high-volume

discharge during the bottling filling phase. The connection of the liquid level

sensor with the control valve that re-fills the tank, is what we refer to as a

System. It is the system of filling the tank. Note that it does not include the

draining, that would be another System.

Another example of a system could be the detection of a

bottle being present within the filling location and the valve filling the

liquid into the bottle. Note that the System is kept to a minimum number of

interactions between Sub-Systems. This means that the System which is

responsible for filling the bottles does not include moving the bottle in and

out of the filling location.

Another example of a System could be the maintenance of

pressure within the product liquid fill line. The Sub-Systems utilised within

this System are the product liquid fill line pressure sensor and the VSD for

the motor connected to the product liquid fill line’s pump. The interaction

between these sub-systems (i.e. when the pressure drops below a certain amount

- the pump starting) is what is known as the System. The System is maintaining

the set pressure of the product liquid fill line.

Ideally, it should be possible to list all the Systems

utilised within a PLC as well as having each System residing in its own

independent program module. This allows for faster fault finding as well as

faster and more cost-effective upgrades.

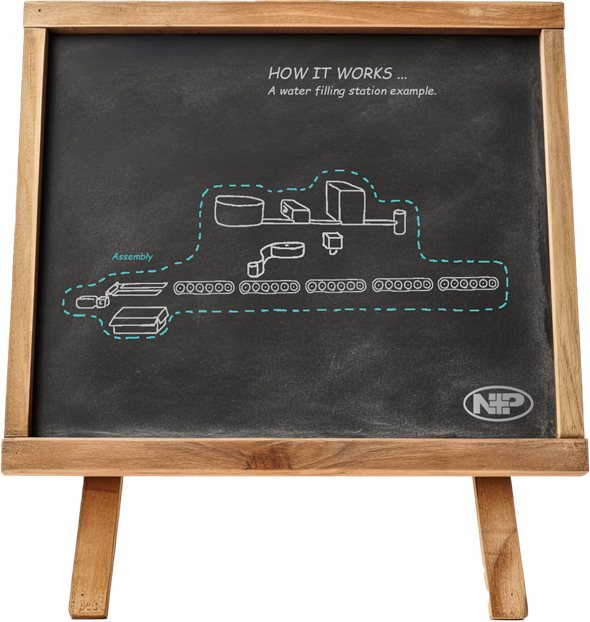

What are Assemblies?

Finally, Assemblies are the collection of Systems which

ultimately transfer a product from its raw form to a more finished product.

An example of an Assembly is the filling, labelling,

and capping of water bottles. The Assembly has various Systems (tank storage

level management, bottle filling, bottle capping, conveyor movement, bottle

labelling etc).

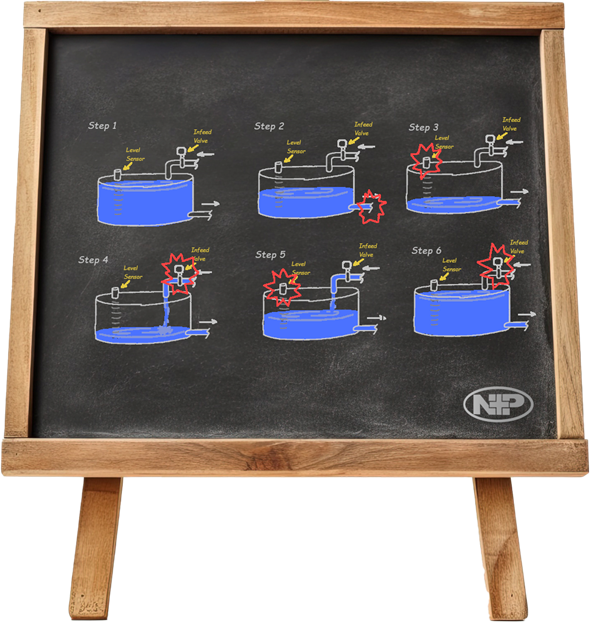

What are Sequences?

Sequences are essentially a storyline or pathway of how a

machine is to operate. They are utilised in both System level programming as

well as Assembly level programming[1].

It includes both the management of the outputs (controlling valves and VSDs) as

well as monitoring of inputs (buttons and sensor readings). It is the logical

progression of events during a machine’s operation.

An example of a sequence is the product tank liquid level monitoring

System. Initially, when the tank is full, the System (filling the tank) is in

the Standby Stage. Once the water level drops below a set low level

point, the Sequence then goes into a Filling (Run) Stage. It then

subsequently triggers the inlet valve to open. Once the product liquid level

climbs to the high point, the Sequence goes into a Stop Stage which then

triggers the inlet valve to close. Once the Sequence detects that the valve has

closed, and the level is no longer increasing then the Sequence switches to the

Standby Stage again. This process is then repeated as often as required.

Sequence programming is typically included within the System

and Assembly programming modules.

[1]

Not to be confused with the low-level programming that is transferred to the

PLC. For the purposes of this framework Assembly Programming is that which

involves the interconnection programming that links the system programming.

What are Stages

Stages are the sub-set of a Sequence. They are the steps in

which a machine takes as opposed to the entire storyline (which would be

referring to the Sequence). Depending on what conditions are present at the

time, the machine will jump to the required Stage as pre-determined within the

Sequence programming. For example; if an operator presses the Run button while

the machine is in the Standby stage, the machine will progress to the Starting

stage.

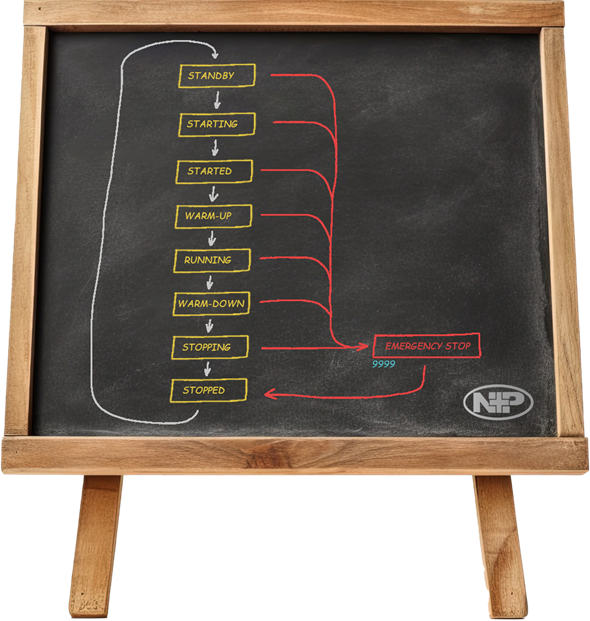

As part of this framework there are 10 fundamental stages;

1. Standby

2. Starting

3. Started

4. Warm-up

5. Running (Initial)

6. Running (Manual)

7. Running (Auto)

8. Warm-Down

9. Stopping

10. Stopped

Depending on the system requirements, there may be more

present, however as a fundamental all of these stages should exist in every System.

This is to ensure that in the chance that the System needs to be upgraded, and

or improved, these items are not having to be added and integrated at a later

stage into a working system. Making major modifications into a working system

can increase the risk of equipment damage and malfunction during programming.

This framework allows for greater flexibility when adding stages (which is a common request during the life cycle of equipment). If implemented across multiple machines it allows for greater understanding by programmers and technicians during breakdown. It also allows for greater visibility of System status across all levels within the machine. It also lowers the risk of incorrect programming. This method of programming also allows for safer cut-overs when programming on live equipment.

Essentially Sequencing operates on an indexing variable. The

corresponding values for each of the stages are detailed below.

Standby (Index: 0000 → 0999)

Within this Stage the System is not operating and is waiting

to be initiated. This can either be manually triggered via operator

intervention or via an AUTO Run Switch / Latch. Once a Sequence has finished

its Stopped Stage, it should return back to this Stage. During this Stage, no

output should be operating.

Starting (Index: 1000 → 1999)

This Stage typically involves the System conducting

pre-start checks before running. These can include making sure consumable

levels are correct, and or doors are closed etc. This is different from fault

interrupters which occur during the system Run Stages. These checks are usually

those System readings which are present while the system is operating.

An example of this would be the System checking the pressure

on the product liquid fill line. As the system would not be running, the

expected pressure reading should be near zero. If the System detects a high-pressure

reading, then the System could conclude that there is a fault which maintenance

crews need to investigate.

This Stage can also include other functions like opening

supply lines to the System.

Started (Index: 2000 → 2999)

This Stage is essentially the point in which the above

checks have passed, and the System can then progress to the next Stage. This Stage

can also include checks that the actions taken in the previous stage have

successfully executed (for example checking those pressures in the supply line

(downstream of the valves are within an expected range).

Warm-up (Index: 3000 → 3999)

This Stage is typically used for warming equipment up (if

required). It can be used for charging lines as well as for testing liquid

lines at lower pressures prior to engaging full pressure (which would be

present during normal operation). Thereby reducing the amount of spillage in

the event of pipe rupture. Having the system start at a lower pressure may also

reduce the effects of hydraulic shock. When using this stage, a timer will be

needed, which switches over to the Running stage (4000) after a pre-determine

amount of time. If this Stage is not required, then program the system to

immediately jump to the next Stage (4000).

Running [Initial] (Index: 4000 → 4999)

This Stage is the initial Stage of Running. Within this Stage

the System typically determines which Running mode is required. It can do this

through checking user inputs and or equipment states. An example of this is if

the user has selected AUTO on the mode switch on the control board. As part of

this Stage, the System would check the state of that switch and then change the

Stage to Running (Auto) (6000).

Typically, when a Stage is switched out (for example being

switch out of AUTO to Manual mode by and operator), the Sequence will then be

switched back to this Stage (4000) which will then determine that the next

stage will be Run Manual mode (5000).

Running [Manual] (Index: 5000 → 5999)

In this Stage the System / Assembly is being manually

ran. System setpoints are typically defined by the operator / maintenance

staff. When the System / Assembly detects a change in Run Mode (for example Manual

→ Auto) then the Stage will be changed to Running (Initial) (4000).

Running [Auto] (Index: 6000 → 6999)

This Stage is the typical stage that’s going to be employed most

of the time. For complex Systems which may have several steps, additional Stages

can be added (for example 6001, 6002, 6003 and so forth).

An example of this could be a product liquid fill line pressurisation

system which operates at two pressures (Standby and Fill). When the System

isn’t filling bottles with liquid, the Stage is set to Running Auto Standby

(6000). When the System detects that it is about to fill a bottle (via

monitoring another System’s status which is responsible for filling product

into the bottles) then it sets its own Sequence Stage to Running Auto Fill

(6001). When the System responsible for Bottle Filling changes to completed,

the Pressure System sets its own Sequence back to the Running Auto Standby

(6000) stage.

Warm-Down (Index: 7000 → 7999)

Please refer to Stage Warm-up (3000) as this is the reverse

function of that Stage.

Stopping (Index: 8000 → 8999)

Please refer to Stage Starting (1000) as this is the reverse

function of that Stage.

Stopped (Index: 9000 → 9499)

Please refer to Stage Started (2000) as this is the reverse

function of that Stage.

Operator Intention (Index: 9500 → 9899)

System Fault (Index: 9900 → 9998)

This Stage is for setting the system into a state which is

acceptable under any fault conditions. The purpose for employing a Fault Stage

is to ensure that when a fault does occur, the System is then deliberately

interrupted, and requires a deliberate action by the operator and or

maintenance to acknowledge the fact that an error has occurred.

Emergency Stop (Index: 9999)

IMPORTANT: This Stage is not a replacement for having

a certified safety system. This is a supplementary and informative function to

allow the system to return to a state ready for resetting.

The emergency stop Stage is purely for stopping the control

system outputs and ensuring that they ready for resetting. This stopping

function is purely supplementary to the emergency control system and is only

there if the safety system fails, the control system isn’t forcing the outputs

to trigger. It is also, used for setting System / Assembly into a state ready

for it to be return into service.

In the same manor that the Fault Stage works, the system

requires acknowledgement from the operator and or maintenance staff that the

system has been placed into emergency mode. Within this section, any emergency

indications which are added, must not be latching in nature.

![NP Logo Basic Small [Metal] NP Logo Basic Small [Metal]](https://np-projects.net/wp-content/uploads/2024/03/NP-Logo-Basic-Small-Metal.png)